Key Terms and Definitions in Light Steel Frame (LSF) Construction

1. Stud

Definition: A vertical structural member, generally used in framing walls, to support horizontal members or surfaces.

Role in LSF: Studs are usually spaced at regular intervals, typically 400 to 600 mm, providing vertical support within a wall frame. In LSF, steel studs are used instead of wood, which offers higher strength-to-weight ratios and greater resistance to environmental conditions.

2. Track

Definition: The horizontal component that caps the studs at the top and bottom of a wall, forming the framework’s outline.

Role in LSF: Tracks hold the vertical studs in place and transfer loads from the walls to the foundations. Tracks are essential in stabilizing the overall structure and are often made of galvanized steel to prevent corrosion.

3. Joist

Definition: Horizontal structural members that support the weight of floors or ceilings.

Role in LSF: Joists in LSF construction are steel members arranged horizontally to distribute loads to the vertical supports (studs). Steel joists offer lightweight solutions that enhance floor performance without adding excess weight to the structure.

4. Sheathing

Definition: A layer, usually of plywood, fiber cement, or another composite material, applied over the studs or joists.

Role in LSF: In LSF structures, sheathing reinforces the wall and floor frames by adding stiffness and distributing lateral loads across a larger area, reducing the need for additional bracing.

5. Bracing

Definition: Structural components used to stabilize the frame and resist lateral forces, such as wind and seismic activity.

Role in LSF: Bracing is critical in LSF construction, especially in regions prone to earthquakes or strong winds. Steel straps, cross bracing, and other metal elements are used to provide stability and prevent warping or displacement.

6. Load-Bearing Wall

Definition: A wall that supports weight from above, such as a roof or upper floor.

Role in LSF: In LSF, load-bearing walls carry the building’s primary structural loads. The use of steel allows for slimmer wall profiles without sacrificing strength, maximizing usable floor space.

7. Non-Load Bearing Wall

Definition: A wall that does not support any structural load from above.

Role in LSF: Non-load bearing walls in LSF are typically used to divide rooms or provide aesthetic features. Since they do not carry loads, these walls can be more flexible in terms of design and material use.

8. Truss

Definition: A triangular framework used to support roofs or large spans within buildings.

Role in LSF: Steel trusses are lightweight yet robust, ideal for spanning large areas while keeping the overall weight of the structure low. They offer better resistance to forces compared to traditional wood trusses and are less susceptible to warping or decay.

9. Insulation

Definition: Materials used within the wall cavities or on the building exterior to control thermal performance.

Role in LSF: Proper insulation in LSF structures is essential to ensure energy efficiency. Since steel is a good conductor of heat, additional insulation, such as foam boards or spray insulation, is used to prevent thermal bridging.

10. Panelization

Definition: The process of assembling wall, floor, or roof sections in a factory before transporting them to the site.

Role in LSF: LSF construction often utilizes panelization, where components are prefabricated, speeding up on-site assembly and reducing labor costs. Panelization improves quality control and minimizes waste, aligning with sustainable building practices.

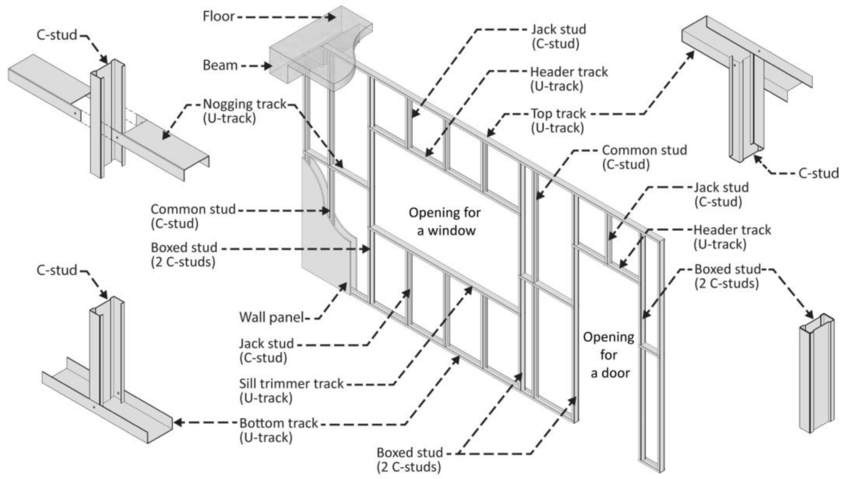

11. C-Section

Definition: A type of steel member shaped like a “C,” often used in framing for studs, joists, and rafters.

Role in LSF: C-sections are widely used in LSF due to their high load-bearing capabilities relative to weight. The shape helps resist twisting and bending, ideal for both vertical and horizontal applications. Engineers select C-sections based on their depth, flange width, and thickness to suit various structural needs.

12. Z-Section

Definition: Another steel member with a shape resembling the letter “Z,” commonly used for purlins and girts in roofing.

Role in LSF: Z-sections are favored for roofing and wall applications because their shape allows them to overlap efficiently, creating a continuous structure that can handle wind and snow loads well. They are ideal for connecting roof and wall panels and provide lateral support against horizontal loads.

13. Lipped and Unlipped Sections

Definition: Variants of C- and Z-sections where “lipped” means a small lip or flange is added to one edge for extra stiffness.

Role in LSF: Lipped sections offer improved resistance to bending, commonly used in places requiring greater strength. Unlipped sections, while not as rigid, are lighter and better suited to non-load-bearing partitions or areas with minimal structural requirements.

14. Fire Resistance

Definition: The ability of a structure or material to withstand fire exposure without failing structurally or allowing heat transfer.

Role in LSF: Steel is non-combustible but has a high thermal conductivity, which means fire-resistant insulation is essential. Techniques like encasing steel members in fire-rated sheathing, using intumescent coatings, or adding fire-resistant barriers help LSF systems meet fire safety standards.

15. Thermal Bridging

Definition: A phenomenon where conductive materials (like steel) create a “bridge” for heat to travel through, reducing energy efficiency.

Role in LSF: In LSF buildings, thermal bridging is minimized using thermal breaks, where less conductive materials (like foam or neoprene) are placed between steel sections. This ensures that internal and external temperatures are better controlled, enhancing the building's overall energy performance.

16. Sound Insulation

Definition: Materials or methods used to prevent sound transfer between rooms or from outside.

Role in LSF: Steel frame walls are thinner, so sound insulation is often required to meet noise reduction standards. Techniques such as adding acoustic insulation, resilient channels, or double-layered drywall help achieve superior soundproofing in LSF structures.

17. Load Transfer Paths

Definition: The routes through which loads (like weight from a roof or wind forces) are transferred through the building to the foundation.

Role in LSF: In LSF construction, load paths are carefully designed to direct forces efficiently down to the foundation. This means considering lateral and vertical loads in both design and material choice, with steel frames offering predictable, reliable load distribution.

18. Fasteners and Connectors

Definition: Components used to connect steel members in LSF systems, such as screws, rivets, and clips.

Role in LSF: Unlike wood, steel requires specialized fasteners that don’t degrade or loosen over time. Galvanized screws or rivets are preferred due to their strength and rust resistance. For critical connections, engineers might use specialized brackets or connectors that help resist shearing forces.

19. Lateral Stability Systems

Definition: Structural systems designed to resist horizontal forces (e.g., wind and seismic loads).

Role in LSF: Bracing, shear walls, and moment-resisting frames are commonly used in LSF structures to provide lateral stability. This is crucial in regions with high wind or seismic activity, where LSF systems excel due to their flexibility and ability to dissipate forces without cracking or breaking.

20. Corrosion Resistance

Definition: The ability of materials to resist degradation due to environmental exposure, particularly in coastal or humid areas.

Role in LSF: Corrosion can weaken steel over time, so protective coatings like galvanization (a zinc layer) or powder coatings are applied. In highly corrosive environments, additional protective layers, such as epoxy, are used to extend the lifespan of steel members.

21. Modular Construction

Definition: A method where building sections or modules are prefabricated in a controlled environment and then transported to the site for assembly.

Role in LSF: LSF is well-suited to modular construction. The lightweight nature of steel frames makes transporting and assembling these modules efficient, resulting in shorter build times and less disruption on-site. This approach also allows for a high degree of customization in each module, tailored to the building’s design needs.

22. Cladding

Definition: The external layer or "skin" of a building, providing protection and aesthetic appeal.

Role in LSF: LSF structures often feature cladding materials such as fiber cement, vinyl, or aluminum. These materials not only protect the building from weather but also enhance insulation and add visual appeal. In steel framing, cladding is usually non-structural and installed over sheathing.

23. Diaphragm Action

Definition: The way horizontal elements (like floors and roofs) in a structure transfer lateral forces to vertical elements.

Role in LSF: Diaphragms, usually composed of sheathing materials, distribute lateral loads to walls and bracing systems. This action is particularly valuable in stabilizing steel frames against wind or seismic forces and helps maintain the building’s rigidity.

24. Intumescent Coating

Definition: A fire-resistant coating that expands when exposed to heat, providing insulation to the structural steel beneath.

Role in LSF: Intumescent coatings are often applied to steel members to meet fire safety requirements. When heated, the coating expands to form a protective layer, slowing the heating rate of the steel and providing additional time for evacuation in case of a fire.

25. Punchouts

Definition: Pre-cut holes in steel studs and joists, allowing utilities like plumbing, electrical wiring, and HVAC ducts to pass through.

Role in LSF: Punchouts enable efficient routing of building services without compromising the strength of steel members. They save time during installation and help create a cleaner, more organized layout for building utilities.

26. Reinforced Wall Panels

Definition: Wall panels with additional strengthening, often using heavier steel sections or added bracing.

Role in LSF: In areas that experience high loads or seismic activity, reinforced wall panels are used to bolster resistance against lateral forces. They offer improved performance and stability without the need for thicker walls, maintaining a slim and efficient frame design.

27. Web Stiffeners

Definition: Elements added to steel joists or studs to prevent buckling and improve load-carrying capacity.

Role in LSF: Web stiffeners are particularly important in long spans or heavily loaded areas. They increase the structural integrity of joists, ensuring they can bear the required loads without deformation, which is crucial for the durability of the building’s floors and roofs.

28. Base Plate

Definition: A steel plate attached to the bottom of vertical steel members, such as columns, distributing loads to the foundation.

Role in LSF: Base plates anchor columns and transfer loads evenly to the concrete foundation, reducing the risk of settlement or cracking. They’re often used in conjunction with anchor bolts to securely attach steel frames to the base.

29. Anchorage System

Definition: A system of bolts, ties, or connectors used to secure the building frame to the foundation.

Role in LSF: Anchorage is crucial for stability, especially in windy or seismic zones. In LSF, the steel frame is typically anchored using expansion bolts or chemical anchors to hold the frame securely in place, preventing lateral or vertical movement.

30. Lateral Load-Resisting System

Definition: A system within the structure that counteracts horizontal forces such as wind and seismic loads.

Role in LSF: These systems include shear walls, braced frames, and moment frames, which work together to absorb and resist forces that might otherwise compromise the building’s stability. They’re essential in LSF design to ensure durability and occupant safety in diverse conditions.

31. Deflection

Definition: The degree to which a structural element, like a beam or joist, bends under load.

Role in LSF: Controlling deflection is critical in LSF, as excessive bending can damage finishes or affect the building’s integrity. Engineers calculate deflection limits based on building codes to ensure steel members provide adequate stiffness without excessive movement.

32. Structural Insulated Panels (SIPs)

Definition: Panels made from a rigid foam core sandwiched between two structural facings, often used for walls, floors, or roofs.

Role in LSF: SIPs can be used with LSF as a pre-insulated wall solution, improving energy efficiency and reducing the need for separate insulation. They offer enhanced thermal and acoustic insulation and can accelerate on-site construction by combining structure and insulation into a single panel.

33. Stud Spacing

Definition: The distance between studs in a wall frame, typically measured center-to-center.

Role in LSF: Stud spacing affects structural strength, load distribution, and thermal performance. Commonly set at 400 mm or 600 mm, adjusting stud spacing can improve load resistance or reduce material costs depending on the application.

34. Service Holes

Definition: Holes or cut-outs in steel members to facilitate the passage of utilities and building services.

Role in LSF: Service holes allow plumbing, electrical, and HVAC systems to be seamlessly integrated into the frame. They’re strategically placed to prevent structural weakness and to avoid compromising the frame’s load-bearing capacity.

35. Vapor Barrier

Definition: A layer designed to prevent moisture from penetrating the building envelope and condensing within the wall cavity.

Role in LSF: Steel framing is particularly sensitive to moisture due to the risk of corrosion, making vapor barriers essential in LSF construction. Properly installed vapor barriers help maintain indoor air quality, prevent mold growth, and extend the life of the structure.

36. Composite Floor Systems

Definition: Floor systems that combine steel framing with concrete, wood, or other materials to enhance load-bearing capacity.

Role in LSF: Composite floors are commonly used in multi-story LSF structures to provide robust and durable floors without excessive weight. The integration of steel with concrete or wood improves load distribution and vibration control.

37. Shear Wall

Definition: A wall specifically designed to resist shear forces, which are lateral forces acting parallel to the plane of the wall.

Role in LSF: Shear walls are critical in areas prone to seismic activity. In LSF, shear walls are often made of steel bracing, reinforced panels, or plywood sheathing to stabilize the structure against lateral movement.

38. Moment-Resisting Frame

Definition: A frame designed to resist bending moments and shear forces without the need for additional bracing.

Role in LSF: Moment-resisting frames are used in open-plan layouts, where bracing might interfere with the design. Steel framing is ideal for these applications, as it offers high flexibility and strength, which is essential for seismic resilience.

39. Gypsum Board (Drywall)

Definition: A type of board made from gypsum used to finish interior walls and ceilings.

Role in LSF: Gypsum board is commonly used in LSF construction to cover steel studs, adding a fire-resistant, smooth surface that can be easily finished with paint or other treatments. It also contributes to sound insulation and fire safety.

40. Curtain Wall

Definition: A non-structural exterior wall system designed to protect the building from external elements.

Role in LSF: Curtain walls are often used in multi-story LSF buildings, where they attach to the frame and provide a weather-tight seal. Made from glass, aluminum, or composite materials, they offer aesthetic appeal and allow natural light without adding significant weight to the frame.