USING FOAM CONCRETE AS INSULATION IN LIGHT STEEL FRAMING STRUCTURES

This article explores the use of foam concrete as an effective thermal and acoustic insulation material in LSF (Light Steel Frame) structures. It examines its technical properties, advantages over traditional insulation methods, application techniques, and its compatibility with steel framing systems. The article is ideal for engineers, architects, and builders seeking innovative, sustainable insulation solutions in modern construction.

LIGHT STEEL FRAMING: STEEL GRADES, PROPERTIES, AND STANDARDS

Light Steel Frame (LSF) structures are increasingly popular in modern construction due to their lightweight, high-strength, and durable characteristics. These structures employ cold-formed steel sections, such as studs, tracks, and joists, to create load-bearing frameworks for residential, commercial, and industrial buildings. This summary outlines the steel used in LSF, its material specifications, properties, relevant standards, and key parameters for evaluation.

STANDARD SPECIFICATION FOR STEEL SHEET, CARBON, METALLIC- AND NONMETALLIC-COATED FOR COLD-FORMED FRAMING MEMBERS

This specification covers coated steel sheet used in the manufacture of cold-formed framing members, such as, but not limited to, studs, joists, purlins, girts, and track

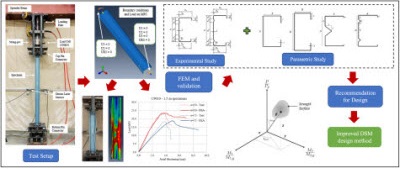

BEHAVIOUR OF LIGHT GAUGE STEEL SECTION UNDER AXIAL COMPRESSION LOADING

Light gauge steel lipped channel sections are being used popularly in shops, factories, automobile engineering and industries on account of their high strength to width ratio, simplicity in construction, flexibility in fabrication and high structural efficiency ...