flexural residual stresses.

Residual Stress Release Test

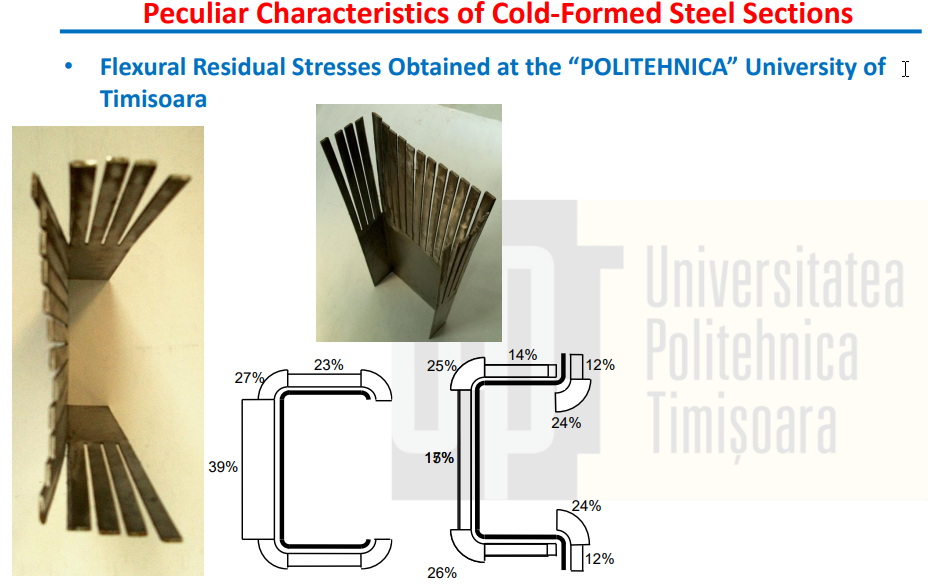

The photos show a cold-formed steel section that has been cut into multiple thin strips using the sectioning method.

When the strips are cut, they are released from the internal stresses that were locked into the steel during the cold-forming process.

As a result, the strips open up like a “fan” or deform slightly.

This deformation reveals the magnitude and distribution of residual stresses inside the original section.

Residual Stress Distribution

The diagrams at the bottom show the percentage of residual stresses measured in different elements of the section (flange, web, corners, lips).

The key point is that these stresses are not uniform across the profile:

-

Some regions show higher tensile residual stresses.

-

Others show compressive residual stresses.

-

Corners typically have different levels due to bending during forming.

Main Message of the Slide

Cold-formed steel sections contain significant and highly non-uniform residual stresses as a result of the cold-forming process.

These stresses influence:

-

Compressive resistance

-

Local buckling behaviour

-

Distortional and lateral-torsional buckling

-

Post-buckling behaviour

The experiments from POLITEHNICA University confirm how these stresses develop and how they are distributed across the section.