Guidelines for Service Holes in LGS C-Sections

In LSF structures, holes are often created in C-shaped sections to allow pipes or cables to pass through. These holes must be designed according to standards to ensure that the strength and integrity of the section are not compromised. Based on existing standards (such as AISI S100 or EN 1993-1-3), there are limitations on the maximum diameter of these holes, typically defined as a percentage of the web height.

General Rules for Holes in C-Shaped Sections:

1. Maximum Hole Diameter:

The diameter of the hole should not exceed 40% of the web height.

For example:

If the web height is 100 mm, the hole diameter should not exceed 40 to 50 mm.

2. Distance Between Holes:

The horizontal distance between holes must be at least 2 times the web height (measured center-to-center).

3. Hole Position:

Holes should be located at the center of the web (neutral axis) to minimize the impact on the bending and shear strength of the section.

Holes should not be placed near supports or fastener connections.

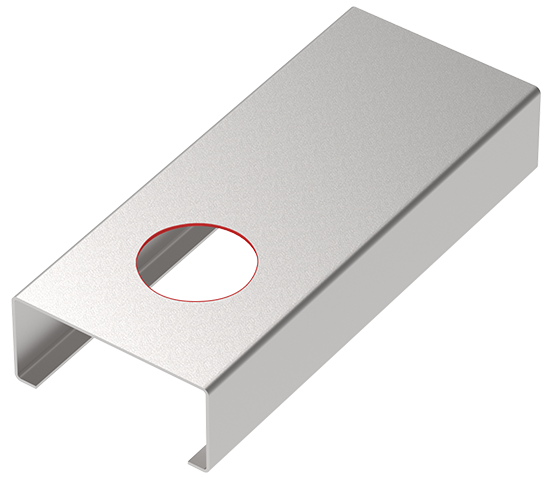

4. Hole Shape:

Holes are typically round or oval, as these shapes reduce stress concentrations.