5 REASONS CFS CONTRIBUTES TO RESILIENCY

“When it comes to framing, there is no more resilient option than cold-formed steel framing (CFS),” writes Jen Edgar, ClarkDietrich corporate product manager, in an article for Metal Construction News.

Resilience, Edgar says, refers to a building’s ability to withstand, respond to and recover rapidly from extreme events in a cost-effective manner. She lists five reasons why CFS contributes to the overall resiliency of a building.

- It’s highly ductile. CFS can easily bend or stretch without breaking when force is applied. This gives it a higher degree of resistance to lateral loads, uplift, and gravity loading, such as those imposed on a structure by seismic or high wind events.

- CFS is non-combustible. According to the Steel Framing Industry Association, both load-bearing and non-load-bearing CFS-framed assemblies are fireproof up to four hours when subjected to tests conforming to ASTM E119.

- CFS is durable. CFS is corrosion resistant. It does not retain moisture and will not harbor mold growth. CFS uses zinc or similar coatings to boost durability and will last hundreds of years before its corrosion resistance deteriorates.

- CFS is impervious to pests. CFS is one of the few building materials completely impervious to termites and other pests in any climate or building type.

- CFS is a highly sustainable material. Steel framing contains on average a minimum of 25% recycled content and is 100% recyclable at the end of its life.

Steel Specified for Resilient City Hall

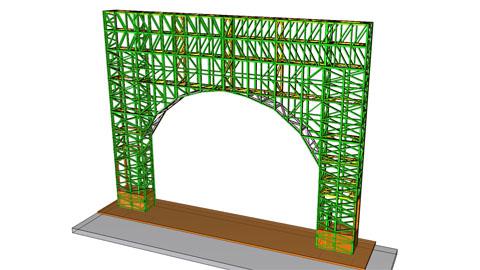

An example of CFS framing’s resilience is the new city hall in Boerne, Texas.

The 45,300-square-foot, $22 million structure was designed by Randall Scott Architects, Richardson, Texas. The architect consulted with general contractor Lee Lewis Construction, Lubbock, Texas, and installer Millard Drywall & Acoustical Construction, Austin, Texas, to specify steel framing solutions for the building’s interior and exterior framing.

According to Metal Construction News, roughly 250,000 pounds of ClarkDietrich CFS framing were used on the project, including the ProSTUD Drywall Framing System, MaxTrak Slotted Deflection Track and Danback Flexible Wood Backing System. The team also leveraged the company’s Clip Express Service for fast and economical steel framing connection solutions.

By using CFS, the new city hall will be a landmark for a very long time.

“Everyone’s going to be really proud to have been a part of a building we hope is going to be standing for the next 100 years or more,” says the estimator for Millard Drywall & Acoustical Construction, Austin.

SFIA Issues Paper on Resiliency

The Steel Framing Industry Association has developed an issues paper, CFS and Resiliency, that relates resiliency to the inherent properties of steel framing.

The paper refers to the comprehensive definition for resiliency developed by the Department of Homeland Security in partnership with the National Institute of Building Science in High Performance Based Design for the Building Enclosure – A Resilience Application Project Report. The document also provides design guidelines for developing resilient exterior envelopes.

Additional Resources